Sale: Steel Mould for Concrete Hollow Square

*Provide customized services

product details

Industry solutions:

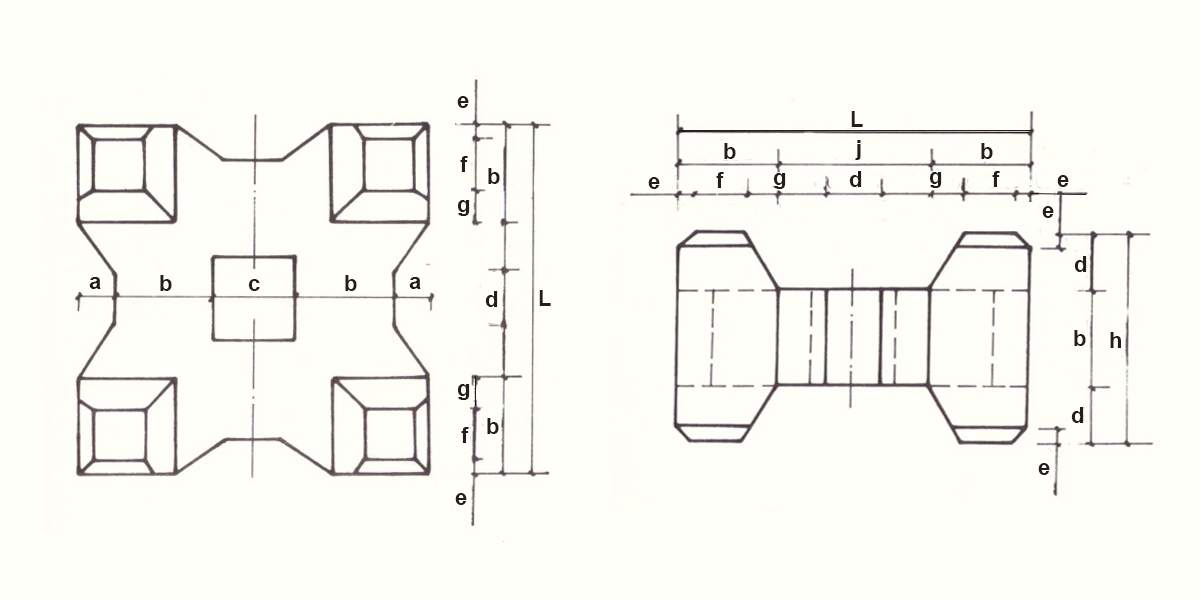

HOLLOW SQUARE DIMENSIONS

At the end of the 1960s, artificial veneer blocks with hollow shape began to develop independently, of which the hollow square is one of the typical representatives. It mainly depends on the friction between the blocks to maintain stability.

Compared with the accropode, the tetrapod and the dolos, the hollow square not only has the advantages of less investment, convenient construction, beautiful appearance and high porosity, but also uses the friction between the adjacent blocks to maintain the stability of individual blocks, so that the difference between the hydrodynamic stability of each block is small, the overall stability is better.

Application Design

The shape characteristics of the hollow square have higher requirements for laying the bottom mold and enlarging the template during prefabrication. The type of the bottom mold template can be determined according to the prefabrication method. Either "sitting" or "standing" can be used for prefabrication. The bottom mold can be made of steel or concrete. No matter what kind of bottom mold is used, its size must be controlled well, the inner size of the bottom die should be slightly smaller than the size of the component (concrete bottom mold), mainly considering the installation of grouting materials; If the steel bottom mold is considered, the bolt connection between the bottom mold and the outer mold may be considered. The outer mold processing size of hollow square must be accurate, each fold surface is flat, the strength and stiffness should be sufficient. When pouring the concrete, it should be strictly layered and vibrated twice. In order to reduce the surface bubbles of the hollow square, the slump of the concrete as low as possible, to 5~6cm is appropriate, while in the vibration at the same time can be used bamboo outside the edge of the seed inserted, with a wooden hammer outside the steel mold edge knocking, try to drive away the bubbles, to ensure the appearance of quality, in order to prevent the vibration surface of the top angle concrete from sliding down, pouring to the top surface, with a top sealing plate, to be finalized after the initial setting before the removal of the cover plate, to ensure the quality of appearace. The demolition time of the outer mold is determined by the temperature. Generally, the mold can be removed after 24 hours. Too early will cause contour loss.

The hollow square requires bottom-up placement, and the bottom block is in close contact with the underwater prism. The upper and lower row block is required to receive the standard, which puts forward higher requirements for the stone slope of the hollow square cushion. Hollow square cushion block stone allows height difference; The water part is no more than 50mm, and the underwater part is no more than 100mm.

Main Feature

First of all, the size of the block is easy to guarantee, and the appearance quality and durability are better. Because the template is shaped and the parts are connected tightly, the shape of the block is more accurate and generally can be controlled within the allowable range of the specification. Especially between the side mold and the bottom tire and the two side mold, the connection is tight, and there is rarely any leakage. Sand line is also very few (flat casting method because of the complexity of the bottom tire, and the joint of the side die is generally difficult to be tight. It is difficult to avoid leakage of slurry); Bubbles and loose tops can also be minimized as long as the operation is proper. In addition, only less than 0.9㎡ surface (2t block) of vertical pouring block needs artificial face lift molding, which is much smaller than that of flat pouring block (flat pouring block artificial face lift molding surface area is not only large, but also has four legs, complex shape, difficult operation). Most of the rest are smooth surface formed by template, smooth and dense, and naturally good durability. The overall quality of the finished products is relatively better.

Secondly, the bottom tire is simple, the side mold and the bottom tire are naturally combined closely, the support template is more convenient, and the work efficiency is higher. Because the combination between the side mold and the bottom tire is good, there is no need to waste material mortar like the flat casting method to deal with the gap between the side mold and the bottom tire, so not only the appearance of the block quality is good, but also save labor and material, construction must be convenient, labor efficiency is also relatively high.

Application Scenario

Hollow square is a construction prefabricated part of the building system, especially for the protection of the harbor tide area. The wave-dampening effect of the shield blocks enables the concrete dam on the shore to withstand the annual storm surge. At present, it has been applied in the construction base project in the southeast of Caofeidian, the Sansha Central Fishing Port area, and the north breakwater of the fourth phase project of Haier Port in Saudi Arabia.

Ningbo Xiaolang Construction Engineering Co., Ltd.

Ningbo Tianyuan Cement Products Co., Ltd.

Yuehu Ginza, Nanzhan East Road, Haishu District, Ningbo City

+86 574 8698 8331

315012

Copyright © Ningbo Tianyuan Construction Engineering Co., LTD All Rights Reserved | Sitemap