Breakwaters are constructed at the periphery of port waters to prevent harbor basin siltation and shoreline wave erosion on sandy and muddy coasts under the influence of waves and tidal currents. They also prevent ice encroachment, ensure adequate water depth and a stable water surface within the port, and meet the requirements for ship berthing, loading, unloading and navigation. As hydraulic structures, they represent an important part of transportation and harbor engineering.

Breakwaters are classified by plane layout into jetties and island breakwaters; by cross-sectional form, they fall into three categories: sloping breakwaters, vertical-wall breakwaters and composite breakwaters. In addition, there are special types such as permeable breakwaters, floating breakwaters, pneumatic breakwaters and hydraulic breakwaters.

Function

1. Defend against wave and ice actions, ensure the stability of harbor waters, and provide safe berthing and operating conditions for vessels.

2. Sandy and muddy coasts feature active sediment movement. Breakwaters intercept incoming sediment, reduce siltation in port waters, and maintain adequate navigable water depth.

3. The inner side of the breakwater can also be used as a berth or equipped with mooring facilities for ship berthing, loading and unloading.

1 Classified by Plane Layout

① Jetty

Jetties can be divided into single jetty and double jetty. A single jetty is a dyke built at an appropriate location on the coast, extending into the sea, with the jetty end reaching an appropriate deep-water area. A single jetty should be adopted when the wave frequency is concentrated in a certain direction, the sediment movement direction is single, or there is already a natural barrier on one side of the port area. A double jetty consists of two jetties built on both sides of the coast, facing each other from a distance, forming a deep-water entrance to enclose a larger water area and maintain the water depth of the channel in the port. Double jetties are suitable for open coasts without natural shelter; especially when waves are large and stronger protection is needed, they can form a good port water area.

② Island Breakwater

An island breakwater is an offshore wave-defense structure in port engineering that is not connected to the coast at either end. It is usually arranged parallel to the coastline and can independently form a sheltered water area or combine with jetties to form a multi-entrance port layout. Its main structure completely relies on overwater construction, with common types including sloping type, vertical type, mixed type, etc., and special forms such as permeable type, floating type and pneumatic type extended from them.

2 Classified by Cross-Sectional Form

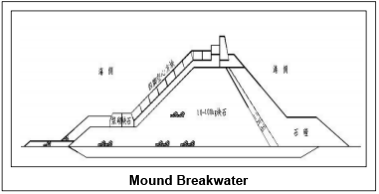

① Mound breakwater

A mound breakwater refers to a type of breakwater with slopes on both sides of its cross-section, constructed by dumping rocks or concrete blocks. The angle between the slope surface and the horizontal plane is usually less than 45°. Its structure is mainly composed of a breakwater core, a cushion layer and armor rocks, and it is divided into two categories: rubble-mound type and artificial concrete block type.

Among them, the rubble-mound type is suitable for areas with small wave energy, while the artificial concrete block type adopts special-shaped blocks such as twisted I-shaped blocks and tetrapods to enhance wave-resistant stability.

It is generally applicable to situations with shallow water depth, poor foundation conditions and sufficient local construction materials. It is not very sensitive to foundation settlement, easy to repair, and relatively simple to construct.

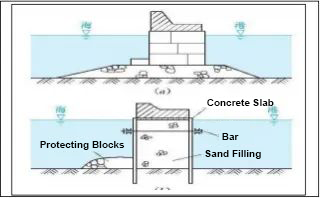

② Vertical Breakwater

The vertical concrete gravity wall of the breakwater relies on its self-weight to resist wave impact and maintain structural stability. Waves reflect in front of the vertical wall and form standing waves. The vertical wall is thus subjected to lateral pressure from standing waves and bottom buoyancy. Therefore, a crushed stone foundation bed is usually arranged beneath the vertical wall during construction to improve foundation bearing capacity. A wave wall is installed on the outer side of the wall crest to dissipate wave energy, which can effectively reduce wave loads and the required self-weight of the wall. The inner side of the vertical wall can also serve as a berthing structure for vessels.This type is suitable for bedrock or relatively dense foundations, as well as water areas with large water depth.

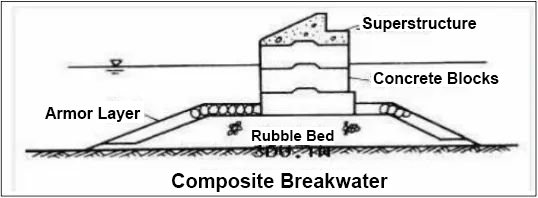

③ Composite Breakwater

The lower part of a composite breakwater adopts sloped rockfill as its foundation, while the upper part is a concrete vertical wall structure, combining the characteristics of both mound breakwaters and vertical breakwaters. From low to high, the wave pattern in front of the vertical wall changes sequentially from standing waves to broken standing waves, breaking waves, post-breaking waves, and finally to climbing water flows. When the foundation bed is relatively high, wave breaking occurs in front of the wall; under such circumstances, the maximum pressure borne by the wall can reach more than twice that of standing waves. The point of application of this pressure is higher than the still water level, which directly affects the stability of the wall. In practical engineering applications, full consideration should be given to the height of the foundation bed and the load generated by wave breaking.

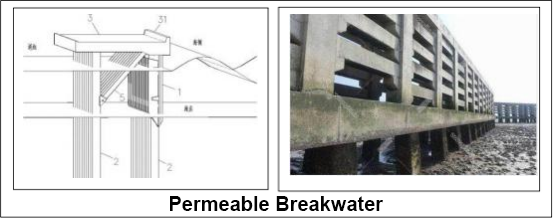

④ Permeable Breakwater

A permeable breakwater is a type of breakwater composed of piers and a wave-blocking structure submerged to a certain depth in water. It achieves the purpose of reducing wave height by blocking the propagation of wave energy. Its principle is based on the characteristic that the fluctuation amplitude of water particles decreases with water depth under deep-water conditions. When the relative water depth is large, it can block waves without touching the water bottom. It is suitable for water environments with large water depth, small wave height and large wave steepness. However, this structure cannot prevent sediment from entering the port nor reduce the interference of water flow on the water area inside the port. The upper structure adopts box-type, perforated baffle-type or vertical wave-blocking structures, while the lower support structure includes pile-type, pier-type and frame-type forms. The bottom of the wave-blocking structure should reach 2~3 times the wave height below the designed low water level, and its top should be 1 time the wave height above the designed high water level (for vertical panels) or equal to the wave run-up value (for sloping panels). The bottom width of the box-type structure is generally about 6 times the wave height. For the baffle-type structure, it is preferable to install two rows of baffles to enhance the wave-dissipating effect.

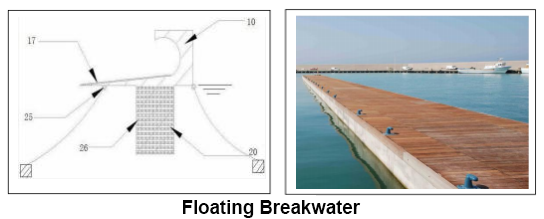

⑤ Floating Breakwater

A floating breakwater is a marine protection facility composed of a wave-dissipating floating body and mooring devices. Its main structure includes a box body, a floating raft or flexible components, which are fixed on the seabed and float on the water surface through anchor chains. It reduces wave energy by using the swing of the floating body to interfere with wave movement. Its wave-dissipating principle includes processes such as wave energy reflection, turbulent energy dissipation and wave force work. Common types include box-type, floating raft-type, wave energy utilization-type, etc. Some structures are equipped with wave-blocking plates at the bottom to form an umbrella-shaped wave-dissipating body. The width of the floating body shall not be less than half of the wavelength. Its advantage is that it can be constructed quickly and moved conveniently, and can be used as a temporary wave protection facility in reservoirs, inland rivers, etc. Its disadvantage is that the strength of the mooring system anchored on the seabed is relatively small.

Ningbo Xiaolang Construction Engineering Co., Ltd.

Ningbo Tianyuan Cement Products Co., Ltd.

Yuehu Ginza, Nanzhan East Road, Haishu District, Ningbo City

+86 574 8698 8331

315012

Copyright © Ningbo Tianyuan Construction Engineering Co., LTD All Rights Reserved | Sitemap